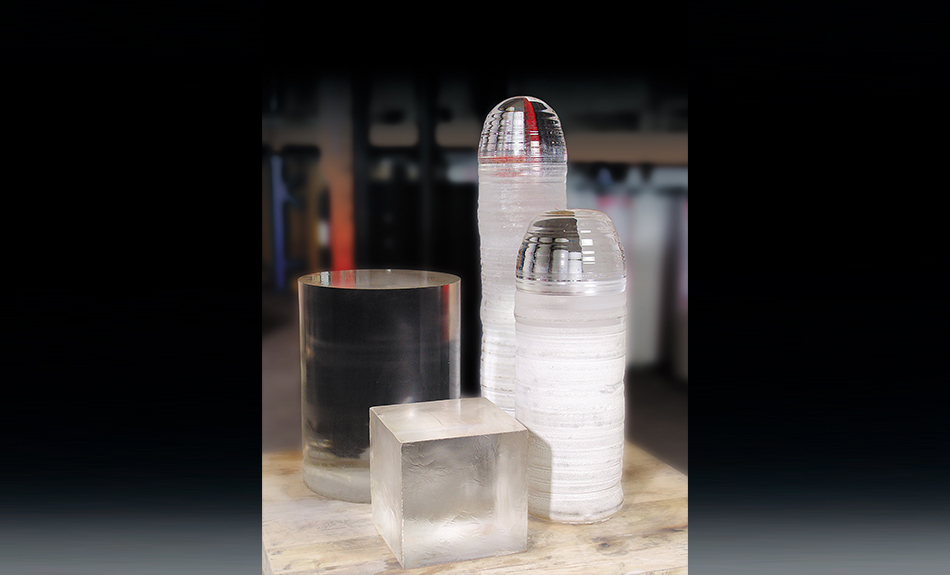

Introduction

FLH211、FLH311、FLH310

Natural quartz ingot made by flame fusion process, less bubble, high transparency and good geometry , optimum rate of utilization.

FLH321、FLH320

High purity natural quartz ingot ,made by flame fusion process, less bubble , high transparency and good geometry , optimum rate of utilization.

FLH321H、FLH320H

High purity natural quartz ingot with lower aluminum、low alkali metal elements.

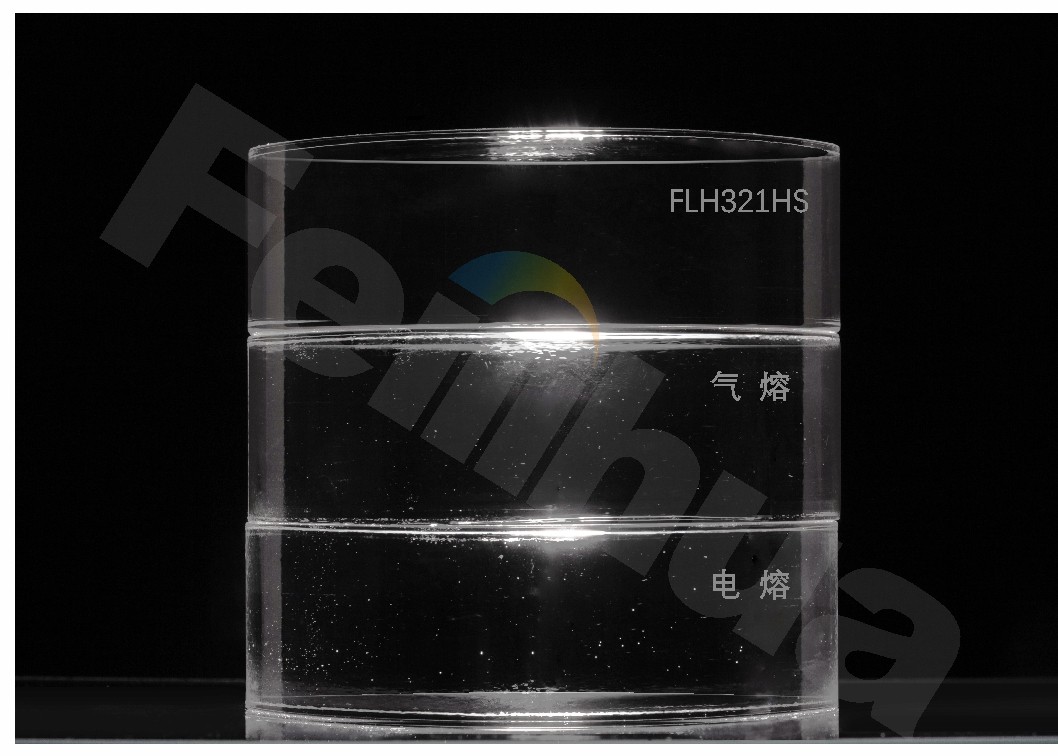

FLH321HS

Almost bubble free, ultra-high purity, low alkali and low aluminum, almost no wrapping, strong high temperature resistance, it is an ideal window material.

FLH321N、FLH320N

Norwegian sand material , made by flame fusion process, less bubble, high transparency and good geometry , optimum rate of utilization.

The material has few bubble in it with excellent transparency and geometric dimension .They are widely used for semiconductor,Optical Fiber, Solar Energy Photovoltaics, Optical Coating/Filming.

Thanks to the few bubbles, high purity, almost no inclusion, high temperature resistant performance and other characteristics,FLH321HS has been widely used in semiconductor advanced manufacturing, optical, chemical processing, UV and high temperature window.

Chemical purity

FLH211/FLH311/FLH310 Impurity Typical Value (ppm)

Al

22.00

B

0.20

Ca

1.50

Co

<0.05

Cu

<0.05

Fe

1.50

K

2.00

Li

2.00

Mg

0.30

Mn

<0.10

Na

2.00

Ni

<0.10

Ti

2.00

OH

~200

FLH321/FLH320 Impurity Typical Value (ppm)

Al

14.20

B

0.08

Ca

0.50

Co

0.50

Cu

<0.01

Fe

0.23

K

0.30

Li

0.50

Mg

<0.05

Mn

<0.05

Na

0.30

Ni

<0.05

Ti

1.30

OH

~200

FLH321H/FLH320H Impurity Typical Value (ppm)

Al

8.00

B

0.04

Ca

0.60

Co

0.05

Cu

<0.01

Fe

0.10

K

0.20

Li

0.40

Mg

<0.05

Mn

<0.05

Na

0.12

Ni

<0.05

Ti

1.40

OH

~200

FLH321N/FLH320N 杂质元素典型值 (ppm)

Al

12.00

B

0.08

Ca

0.30

Co

<0.02

Cu

<0.01

Fe

0.10

K

0.20

Li

0.40

Mg

<0.05

Mn

<0.05

Na

0.40

Ni

<0.03

Ti

1.20

OH

~200

FLH321HS Impurity Typical Value (ppm)

Al

7.50

B

—

Ca

0.60

Co

—

Cu

<0.01

Fe

0.20

K

0.10

Li

0.20

Mg

0.01

Mn

—

Na

0.10

Ni

—

Ti

1.30

OH

~200

Physical Property

Mechanical Properties

Density(g/cm³)

Young’s Modulus(GPa)

Poisson’s Ration

Bending Strength(MPa)

Compressive Strength(MPa)

Tensile Strength(MPa)

Torsional Strength(MPa)

Mohs Hardness

2.2

74

0.16

65

1100

50

30

6-7

Electrical Properties

Dielectric Constant (10GHz)

Loss Factor(10GHz)

Dislectric Strength(V/m)

Resistivity (20℃)

3.74

0.0002

3.7×107

1×1016

Thermal Properties

Strain Point (η=1014.5 ℃)

Annealing point (η=1013 ℃)

Softening point (η=107.8 ℃)

Thermal Conductivity(W/m·k)(20℃)

Specific Heat(20℃)(J/kg.k)

Expansion Coefficient(x10 -7/k)

α :20℃~320 ℃

1080

1180

1700

1.4

670

5.5

Flame Fused Quartz

Consulting Service:0716-8304668、0716-8333088

Add email

Wechat public account

Video number

Recruitment number QR code